QV1812H系列貼片(pian)壓敏電(dian)阻(zu)介紹:

氧(yang)(yang)化鋅壓敏電(dian)阻是一種(zhong)以氧(yang)(yang)化鋅為主體、添加多種(zhong)金屬(shu)氧(yang)(yang)化物為添加劑、經(jing)過空氣中高(gao)溫燒結而制成的多晶半導體陶瓷元件(jian)。壓敏

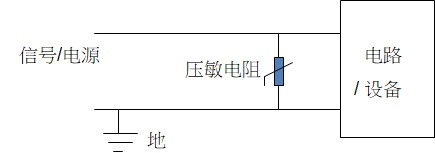

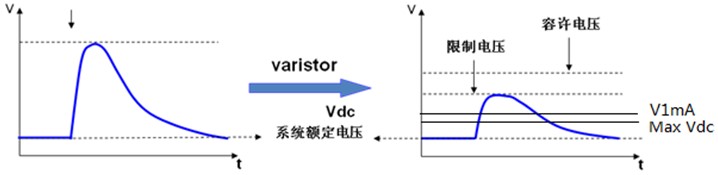

電阻是(shi)一種限(xian)壓(ya)(ya)型(xing)保護器件。壓(ya)(ya)敏電(dian)(dian)(dian)(dian)(dian)(dian)阻和被保護電(dian)(dian)(dian)(dian)(dian)(dian)路元件并聯(lian)在電(dian)(dian)(dian)(dian)(dian)(dian)路中,當電(dian)(dian)(dian)(dian)(dian)(dian)路中出現雷電(dian)(dian)(dian)(dian)(dian)(dian)過(guo)(guo)(guo)電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)、靜電(dian)(dian)(dian)(dian)(dian)(dian)過(guo)(guo)(guo)電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)或(huo)瞬態操(cao)作過(guo)(guo)(guo)電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)

時,利用壓敏(min)電(dian)阻(zu)的(de)(de)非線性特性,壓敏(min)電(dian)阻(zu)會以納秒級時間的(de)(de)響應(ying)速度將(jiang)兩端(duan)電(dian)壓迅速下降鉗位到一(yi)個相(xiang)對固定的(de)(de)安全電(dian)壓值,從

而避(bi)免被保(bao)護(hu)電路元(yuan)件遭受過電壓(ya)的沖擊而損壞。

當施加(jia)于壓(ya)敏電(dian)阻器兩(liang)端(duan)電(dian)壓(ya)小于其壓(ya)敏電(dian)壓(ya),壓(ya)敏電(dian)阻器相當于10MΩ以上絕(jue)緣電(dian)阻;當在壓(ya)敏電(dian)阻器兩(liang)端(duan)施加(jia)大于壓(ya)敏電(dian)壓(ya)的(de)過(guo)

電壓時(shi),壓敏電阻器(qi)的(de)電阻急劇下(xia)降呈現低阻態,從而把電荷快(kuai)速導走,有效地保護(hu)了電路中的(de)其它元器(qi)件不致(zhi)過(guo)壓而損(sun)壞。

多層(ceng)片(pian)式壓敏電(dian)阻(zu)是(shi)貼片(pian)封裝的壓敏電(dian)阻(zu)器,采用多層(ceng)獨石結構,具(ju)備(bei)寄生電(dian)感(gan)小、體(ti)積小、SMT效率高(gao)(gao)、響應時間短、工作溫度高(gao)(gao)、

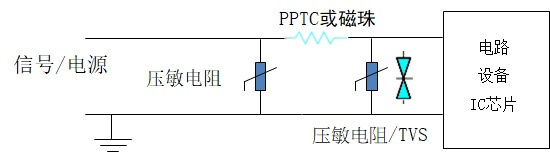

保護能力(li)強的優勢(shi)。恭成科技(ji)QV****H系(xi)列貼(tie)片壓(ya)敏電(dian)阻應用于100V以(yi)內低(di)電(dian)壓(ya)電(dian)路(lu),包括(kuo)DC電(dian)源和低(di)頻(pin)信號線進行(xing)雷擊、浪涌(yong)防護,

吸收并衰(shuai)減(jian)脈(mo)沖(chong)能量,可(ke)以吸收線路(lu)(lu)內部產生的操作過(guo)電(dian)壓(ya)(整流、逆變換(huan)、變壓(ya)器產生的電(dian)磁脈(mo)沖(chong)和線路(lu)(lu)浪涌)及衰(shuai)減(jian)后(hou)的雷電(dian)感(gan)

應過電壓,用(yong)(yong)作(zuo)二級(ji)防護(hu)(可代替SMAJ/SMBJ的(de)TVS),同時部分應用(yong)(yong)于手機(ji)、LCD-TV/STB/電腦等(deng)的(de)通信接口進行ESD靜電防護(hu),替代

TVS使用。

QV1812H系(xi)列貼片壓敏電(dian)阻(zu)特點:

1) SMD小(xiao)型貼(tie)片(pian),節省空間,方便生(sheng)產;

2) 響(xiang)應時間為ns級,響(xiang)應速度(du)滿足各種電(dian)路保護要求;

3) 高浪涌抑(yi)制,同體積浪涌能(neng)力遠大于TVS;

4) 高(gao)溫性(xing)能穩(wen)定,125℃不(bu)降額;

5) 低的(de)漏(lou)電流IL<10μA;

6) 雙向無(wu)極性(xing)保護,鉗位(wei)電壓低;

7) 優于UL94V-0可燃性(xing)等級;

8) 符(fu)合RoHS環保(bao)標準(zhun)

QV1812H系列貼片壓(ya)敏(min)電阻應用范圍:

1) 汽(qi)車(che)電子應用:汽(qi)車(che)的控制(zhi)單元、電液制(zhi)動、ABS / ESP、天窗(chuang)、車(che)窗(chuang)控制(zhi)等負載突降保(bao)護和迅速啟動保(bao)護;

2) 工業儀表、控制與測量設備、安防攝像頭、電(dian)子(zi)電(dian)度(du)表控制板;

3) 5G通訊基(ji)站、網通設備、網絡產(chan)品接口、漏(lou)電(dian)保(bao)護(hu)器控制板;

4) 視頻和音(yin)頻線I / O端口(kou)、高速(su)數(shu)據(ju)線(如HDMI、USB 3.0、IEEE 1394接口(kou)、射頻天線、射頻模塊)的ESD保護;

5) IEC 61000-4-5的浪涌(yong)保(bao)(bao)護(hu),IEC 61000-4-4的EFT保(bao)(bao)護(hu),ESD保(bao)(bao)護(hu)符合(he)IEC 61000-4-2(4級)

QV1812H系列貼(tie)片(pian)壓敏電阻性能參數:

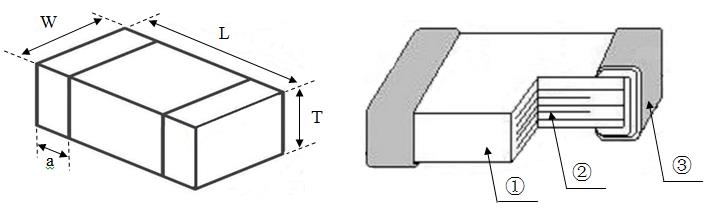

1) 結構與尺(chi)寸;

類型 | L(mm) | W(mm) | T(mm) | a(mm) |

1812 | 4.5±0.4 | 3.2±0.3 | 2.0 Max. | 0.25~1.0 |

部分 | ① | ② | ③ |

組成 | 片式壓(ya)敏電阻(zu)用 ZnO半導體陶瓷 | 內(nei)電極 (Ag 或 Ag-Pd) | 端(duan)電(dian)極 (Ag/Ni/Sn 三層(ceng)) |

2) 電性(xing)能(neng)參(can)數:

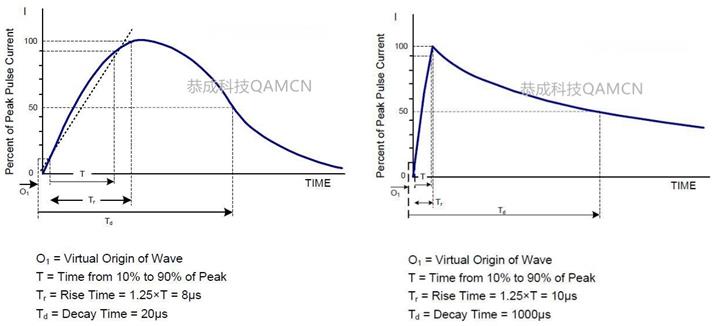

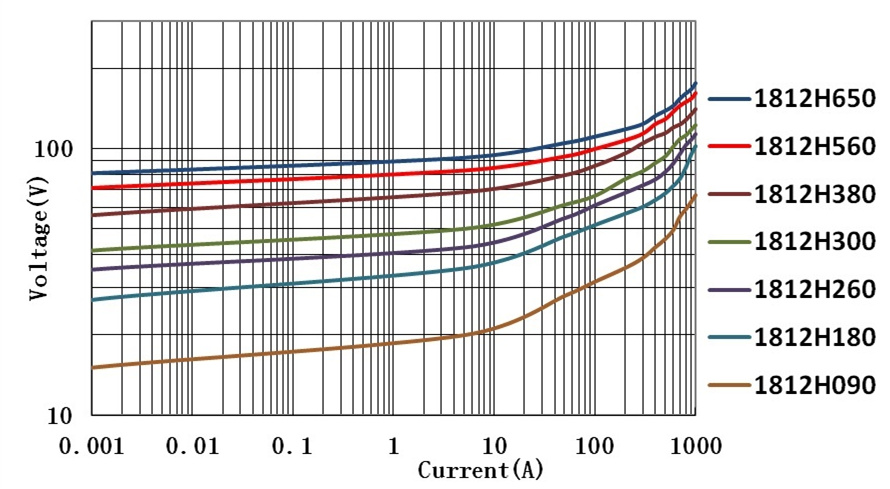

型號 Part No. | 最大工作電壓 Max. Working Voltage | 壓敏電(dian)壓 Varistor Voltage @1mA DC | 最大限位電壓 Max. Clamping Voltage (8/20μs) | 峰值電(dian)流 Peak Current (8/20μs) | 能(neng)量(liang)耐量(liang) Energy (10/1000μs) | |||

VDC(V) | VAC(V) | VB(V) | ΔVB | Vc(V) | Ic(A) | Ip(A) | WT (J) | |

QV1812H090LT | 9 | 7 | 13 | ± 15% | 24 | 5.0 | 800 | 2.5 |

QV1812H120LT | 12 | 9 | 18 | ± 15% | 30 | 5.0 | 800 | 2.5 |

QV1812H140KT | 14 | 11 | 20 | ± 10% | 34 | 5.0 | 800 | 2.5 |

QV1812H180KT | 18 | 14 | 25 | ± 10% | 42 | 5.0 | 800 | 3.0 |

QV1812H220KT | 22 | 17 | 30 | ± 10% | 50 | 5.0 | 800 | 3.0 |

QV1812H260KT | 26 | 20 | 36 | ± 10% | 60 | 5.0 | 800 | 3.0 |

QV1812H300KT | 30 | 25 | 41 | ± 10% | 70 | 5.0 | 800 | 3.5 |

QV1812H330KT | 33 | 26 | 44 | ± 10% | 75 | 5.0 | 800 | 3.5 |

QV1812H380KT | 38 | 30 | 50 | ± 10% | 85 | 5.0 | 800 | 3.5 |

QV1812H420KT | 42 | 33 | 55 | ± 10% | 95 | 5.0 | 800 | 3.5 |

QV1812H450KT | 45 | 35 | 59 | ± 10% | 100 | 5.0 | 800 | 3.5 |

QV1812H480KT | 48 | 37 | 62 | ± 10% | 106 | 5.0 | 800 | 3.5 |

QV1812H560KT | 56 | 40 | 72 | ± 10% | 118 | 5.0 | 800 | 3.5 |

QV1812H600KT | 60 | 45 | 76 | ± 10% | 131 | 5.0 | 800 | 3.5 |

QV1812H650KT | 65 | 50 | 82 | ± 10% | 142 | 5.0 | 800 | 3.5 |

QV1812H750KT | 75 | 55 | 94 | ± 10% | 160 | 5.0 | 800 | 3.5 |

QV1812H850KT | 85 | 60 | 100 | ± 10% | 175 | 5.0 | 800 | 3.5 |

3) 產(chan)品包裝:

類型 | 盤規格(ge) | 載帶 | 每盤數(shu)量(pcs) |

1812 | 7" | 塑載(zai)帶(dai) | 1K |